Since metal buildings undergo a construction process that is markedly different from wooden structures, many prospective property owners question how the building will be anchored. Fortunately, this phase of constructing your brand-new building is rather straightforward and will ensure that it stands secure for decades to come.

Metal carports and other metal buildings are typically anchored with a concrete foundation and steel anchors. There are numerous ways to configure the foundation of your metal building, and some even allow for construction on the bare ground using only concrete piers. Your structure’s foundation depends heavily on your needs and the buildings’ purpose.

The way your metal building will be anchored is also influenced by your geographic area, local construction codes, and the building’s intended use. Each foundation type requires specialized components to keep your metal building in place, all of which are selected with the utmost care. Read on to learn about how the appropriate methods and tools are determined.

Setting the Foundation of Your Metal Structure

There are numerous foundation types available for your building. To determine which will best suit your needs, consider the following questions:

- What type of terrain will your building rest on? Determine the layout and stability of the ground on which you plan to place your new structure.

- What types of horizontal forces will your new building be subjected to? (Examples of horizontal forces include wind and rain.)

- What types of vertical forces will your new building be subjected to? (The primary example of a vertical force is the load that the structure will be expected to bear. How much, and what, will you be storing or housing in the building?)

Anchoring your building starts with pouring a slab of concrete onto your desired construction site. A smooth floor is best for the following building types:

- Garages

- Homes

- Storage facilities

The concrete flooring is integral to the building’s resistance to vertical forces, as well as its capacity to support vertical loads. If you expect to store heavy machinery and equipment in this area, for example, you are likely to reap more benefits from concrete flooring than the average property owner. Those who do not need so much support can leave the natural foundation (dirt or gravel) bare and install a few concrete piers instead. (Source: Metal Construction News)

Adding Support to the Foundation with Anchors

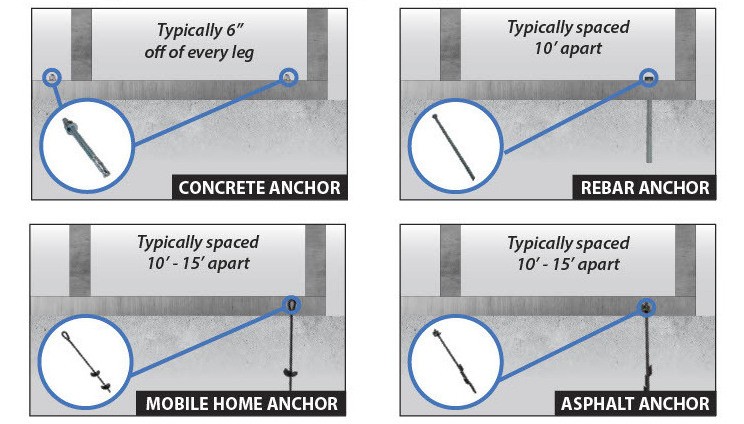

| Type | Application | Placement | Size |

| Asphalt Anchor | For installation on asphalt | Typically spaced 10’ – 15’ apart | 30” |

| Concrete Anchor | For installation on concrete | Typically 6” off of every leg | 6” |

| Mobile Home Anchor | For installation of any unit on the ground, whether it be on soil, gravel, etc. | Typically spaced 10’ – 15’ apart | 30” |

| Rebar Anchor | Pins base-rail in place during construction | Typically spaced 10’ apart | 30” |

Your contractor will install steel rods in either form of concrete support. (You can also have them installed before construction, immediately after the concrete is poured). The rods, also known as “anchor rods” or “anchor bolts,” will function as the point of attachment for the steel structure.

According to the structural engineer, Alexander Newman, these components are critical to providing stability to the steel framing. They also play a direct role in mitigating the impacts of horizontal and vertical loads throughout the entire structure, from the “framing to the foundation.”

Experts say that the best anchor systems are the following:

- Cast-in-place bolts: According to Mike Steiber, a senior product manager that works closely with steel anchoring systems, these are among the most commonly used bolts in steel frame building construction. These are installed once the concrete has cured, even after the frame is erected. Post-installment allows for a wider range of choices in the possible installation sites and eliminates the potential frustration related to shifting anchors installed in concrete that has not yet cured.

- Headed anchors: Newman asserts that these are, by far, the most widely preferred anchor bolts in the industry. These are particularly beneficial in mitigating directional pressures (especially horizontal and uplift forces) exerted by steel frame structures, specifically toward the foundation.

- Although they do help mitigate uplift forces, installing headed anchors may backfire for property owners in areas with especially heavy windstorms such as tornadoes. These anchors would still be considered up to code; however, the American Institute of Steel Construction (AISC) recommends avoiding them in such scenarios.

The anchoring system does not always rely on bolts and concrete alone, however. Designers can even use the earth itself as a source of support for the new building. North Carolina’s Office of State Construction outlined an example of “passive Earth pressure,” wherein grade beams are specially designed to transfer horizontal pressures into the earth around the building’s perimeter.

Note that this is only a reliable option if the soil has been examined beforehand and was deemed conducive to such alternatives. The foundation-to-soil interface must be suitable as well. Further, the soil comprising the building’s perimeter would need to be permanent (e.g., there can be no future expansion plans), so the beams can be securely cast against this or compacted backfill soils. (Source: North Carolina Department of Administration Office of State Construction)

What Contractors’ Consider When Building Foundations

Your contractors will consider the questions listed at the top of this section along with the following details as they plan the casting of your building’s foundation:

- The type of building being erected

- The location of the building as it relates to soil types and health and weather patterns

- The potential presence of rock outcroppings or other formations in the area

Once the site has been thoroughly evaluated, the area will be outlined to guide excavation operations. Extra care is taken for buildings in Northern regions, as the foundation must be installed below the frost line. A failure to consider the frost line when constructing a new building in these areas could result in disastrous effects on the foundation. The ground heaves and swells with the temperature fluctuations, presenting a significant risk of damage during seasonal transitions.

In Conclusion

Metal buildings are anchored according to several factors:

- The vertical and horizontal forces the building may be subjected to

- The type of terrain on which the building will be constructed

- The building’s intended use

Your contractor will carefully evaluate the construction site and advise you on the best foundation materials and techniques to ensure your building remains standing for years to come.