Whether you are putting up a carport or designing a metal barn, you will have to frame a metal building before you can add the sheeting. So, what are the typical framing components of a metal building or carport?

The minimum metal building framing components are typically referred to as rafters and columns. As the type of the metal building changes, the framing will also include bows, braces, base rails, leg posts, and trim. All of these components will be made of metal.

Of course, the framing components used in any given metal building depend largely on the type and purpose of the building. Keep reading for further discussion of these factors and definitions of the various framing components.

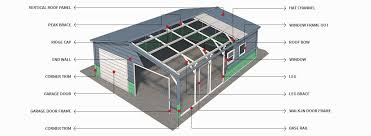

What Are the Typical Components in Metal Building Framing?

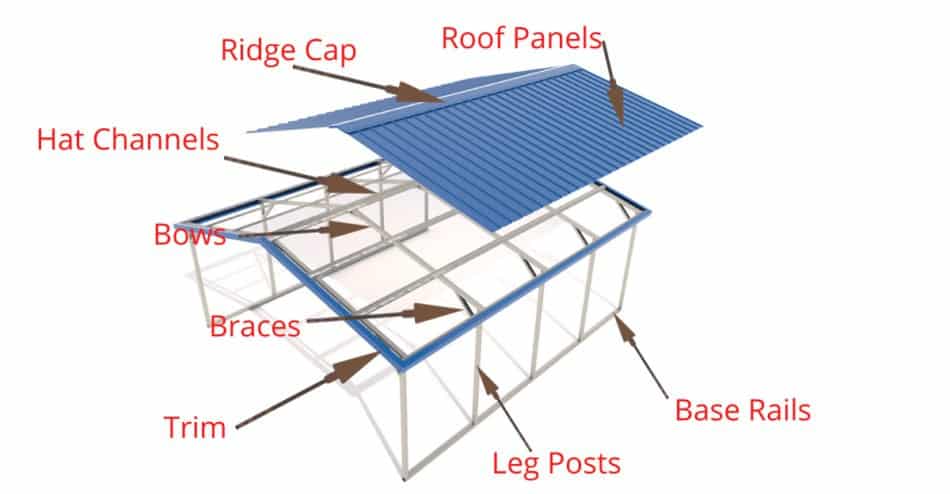

Metal buildings can consist of several different framing elements. How many of these elements are used depends on the size and purpose of the building. Typical framing elements of a metal building are the columns and rafters. However, framing elements for carports and prefabricated metal buildings include hat channels. bows, braces, base rails, leg posts, and trim.

Each component in the framing of a metal building is essentially defined by where it connects to other framing components:

- Ridge Cap connects to Panels

- Hat Channels connect to the Bows.

- Bows connect to Braces.

- Braces connect to Leg Posts.

- Leg Posts connect to Base Rails but are there to support wall sheeting, not roofing.

- Trim connects to both Leg Posts and Bows at the edges of the roof to give a nice finish.

A carport – Simply a metal frame with a cover to keep off the sun and rain – is the simplest of metal buildings and contains all of the same framing components as a metal garage and or barn. However commercial buildings, on the other hand, would contain all of the components listed above, as well as secondary framing components for stability and durability.

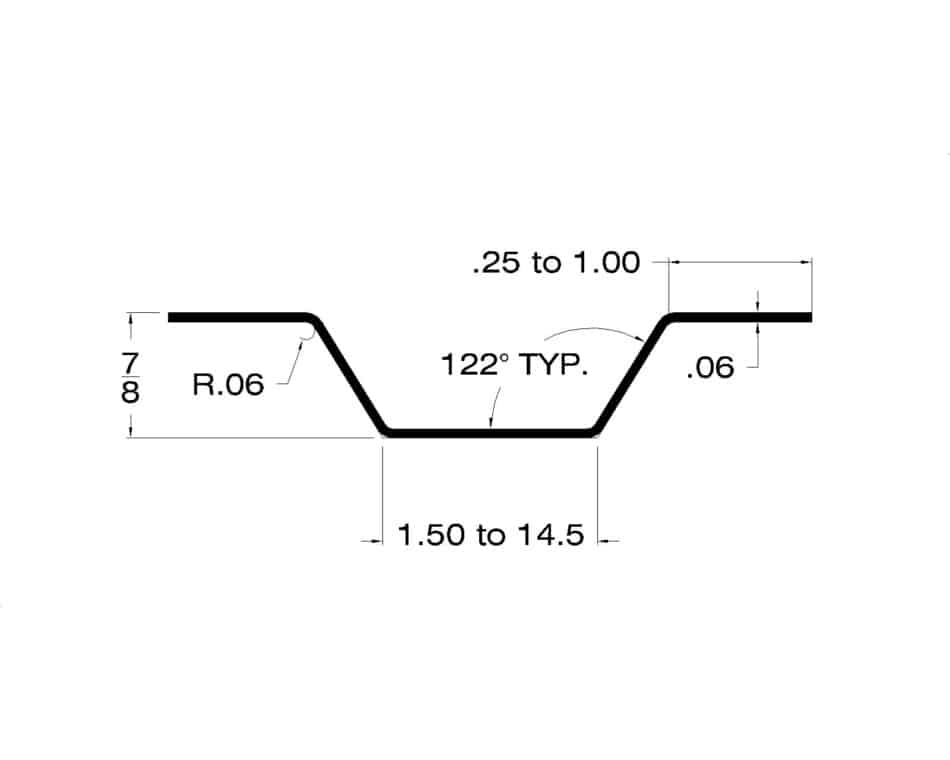

Hat Channels:

A galvanized steel component is used to create a vertical roof orientation. The hat channel also provides more rigidness for a stronger structure. They are galvanized steel, usually providing a corrosion-resistant framing component less prone to warping or bending underweight. Hat channels are often used by masons and builders to level uneven walls or ceilings.

The hat channels get their name from their hat-like shape. Hat channels contain a grooved metal piece which is perfect for leveling out walls or ceilings. The shape is also ergonomically-friendly, making it easy to install without much hassle at all.

Hat channels can be made from a variety of different materials, including steel and aluminum. Hat channels are heavily sought after by masons and builders as this is the most affordable way to even out walls. Not only do they provide advantages in the construction process, but they also protect your interior and exterior frames from fire, moisture, corrosion, and other dangerous hazards.

Ridge-Cap:

A transition piece covering the ridge of the roof. The ridge cap is normally color-matched with the roof panels. However, if the customer wishes to change the color it must be specified when completing your order.

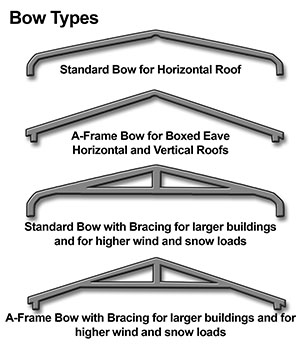

Bows: A single piece of square tubing used to make the roofing member of a building. The tubing can be made from either 14 gauge or a 12 gauge steel. Without bows, a metal building or carport cannot exist. In commercial buildings, manufacturers typically use steel trussing also 14 gauge galvanized steel. Smaller metal buildings such as carports or small tool sheds may use the same hollow square tubes called rolled steel for the leg posts. Rolled steel columns are lighter and easier to erect but support much less weight.

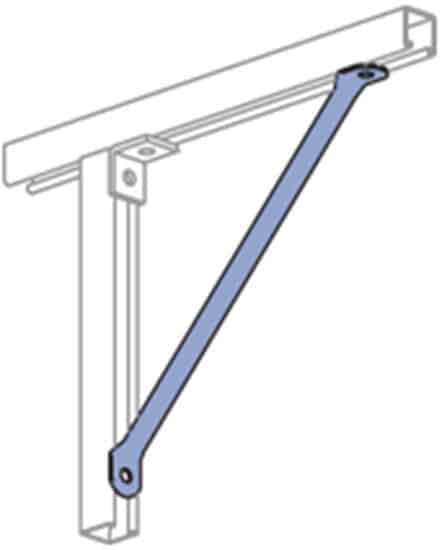

Braces:

Braces are U-shaped channels that are used to reinforce the structure of a building. For buildings in which the braces are optional we recommend 2′ braces on buildings shorter than 8′ and 3′ braces for buildings 9′ or taller

Base Rails:

The square tubing on the base of the building onto which the legs are attached to.

Leg Posts: Legs are the vertical tubing that connects the bows (top) to the base rail (bottom). The leg height varies depending on the type of building.

Trim: Trim gives the roof and building corners a finished and more aesthetic view.

Additional Forms of Bracing

Columns, rafters, purlins, eaves, and girts make up the framing of many metal buildings, and may not be present in all metal buildings, depending on size and purpose. However, in the case of a large metal building such as a stadium or large barn, the support of the building may be augmented by cross bracing.

Bracing is typically comparatively smaller metal poles that connect between the framing components to add structural stability. They are frequently attached in an X-formation for maximum stability.

Metal Carports and Standards of Construction

While there are many framing components used when erecting a metal building, not every metal building will be built using all of them. Simpler metal structures only require basic columns and rafters. In contrast, large metal buildings can include every metal framing component plus metal bracing.

Today’s metal carports meet a much stricter standard of construction than those built in previous decades. If you’re wondering when your older and aging carport was built, you’re likely ready for a replacement. Pre-engineered buildings are more reliable, affordable, and easier to customize than the old stick-built designs. Check out what’s available today to find a great replacement for any worn carport on your property.

Pre-Engineering

The pre-engineered design of your building means that all the framing pieces are cut, welded, and drilled before they arrive at the construction site. This reduces construction time, ultimately saving you money and allowing you to get up and running faster.

Resistant to damage from high winds, heavy snow, fire, and termites. The durability of our steel buildings means less money spent on maintenance over time. This also translates to less expensive insurance fees and peace of mind that your assets are protected.

Choosing the Right Metal Structure for Storage

Not all carports or metal buildings will work equally well for your storage in particular. Consider a model that has a wide enough entryway that is wide enough to fit your personal belongings, vehicles, and any other items you want to store or protect.

If you can’t get your items in or out of the metal structure, obviously it won’t work as a good storage option. Add an extra two or three feet on both sides so that vehicles don’t scrape against the door frame.

Enclosed metal structures are a much better choice than open models since they keep out sunlight, moisture, and even pests when sealed tightly. Yet even an open metal carport offers more protection from fading and wind than none at all.

Finally, consider a pull-through design that features doors at both ends of the building. You can simply pull in, unload a boat or trailer, and depart without worrying about backing into the carport with your view obscured.

Recent Comments